Main Project Contact:

Patrick Gall

Project Start Date:

December 2017

Project End Date:

March 2023

Project Name:

Manufacture and Use of Cardboard Pellets in Inuvik, NT

ARI Team:

Patrick Gall

Overview:

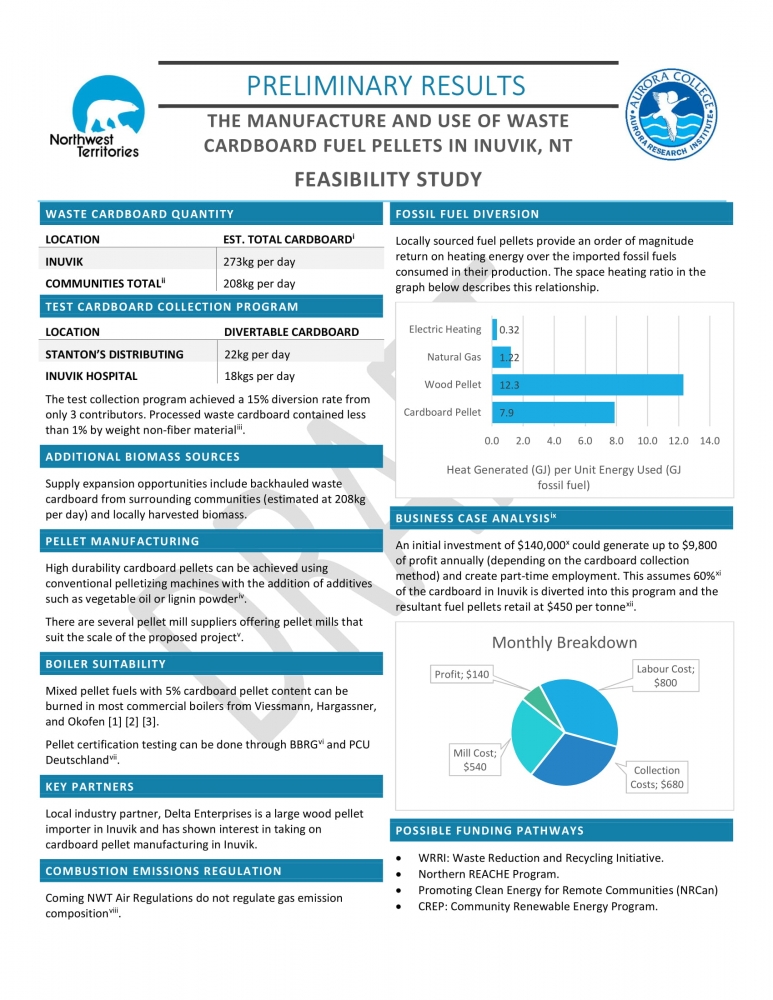

The goal of this project is to build an understanding around what is technically possible, economically feasible, and environmentally beneficial in the diversion of waste cardboard from the Inuvik landfill for the manufacture of cardboard heating pellets. The project began with a pre-feasibility study investigating the technical barriers of manufacturing pellets local to Inuvik and evolved into a pilot project capable of manufacturing 60 tonnes of heating pellets per year.

A Sample of Cardboard Pellets Made in Inuvik

Objectives:

The objective of this project is to build an understanding related to cardboard fuel pellet manufacturing and its impacts. In order to build this understanding, the research team generated the following questions:

Technical Challenges:

- Can we reliable make pellets from cardboard?

- How easy are these pellets to burn?

- Is burning these pellets safe?

Economic Analysis:

- What quantity of waste cardboard is available to divert?

- How much will it cost to make these pellets from waste cardboard?

Environmental Effects:

- What is the composition of the combustion emissions of these pellets?

- What effect do we have by removing the cardboard from the landfill?

Location:

Although the analysis performed project throughout this project dealt with the economics and environmental impacts of cardboard pellets specific to Inuvik, the same type of analysis could be performed for other communities where similar conditions exist.

In Sept 2019, a pellet mill was installed in Inuvik with the initial purpose of manufacturing test cardboard pellets and eventually to be used to commercial production of fuel pellets. The video below shows a virtual tour of the Inuvik Pellet Mill.

Video Tour of the Inuvik Pellet Mill

Timeline & Methods:

The project began with the pre-feasibility in Sept 2017. The results of this study permitted the research team to seek more funding to both expand the scope of the study as well as to install test infrastructure in Inuvik. In sept 2019, a pellet mill was installed in Inuvik in partnership with Delta Enterprises.

For the summer of 2021, the research team is planning to perform follow on training sessions and more fuel testing with the goal of transitioning the pellet mill to commercial production for the fall.

The video below provides a good overview of the whole project.

Virtual Speaker Series - Creating Heat Through Waste

External Partners:

Inuvik Regional Hospital

Stanton's Distributing

Town of Inuvik

Arctic Energy Alliance

GNWT - ITI

GNWT - Energy

CIRNAC Northern REACHE

Delta Enterprises

Media:

Cardboard-to-pellet biomass research gets $95K grant - CABIN RADIO

Inuvik pellet project aims to turn waste cardboard into warmth - CBC NEWS

Keywords:

Biomass, waste diversion, heating, pellets, wood, cardboard, recycling, shredding

Additional Documents:

Pre-feasibility Study

Greenhouse Gas Summary Handout.

Updated May 2021